Finding lead in home drinking water systems is not uncommon, nor is it ascribed to only very old structures.

In fact, lead-leaching components can be found in homes as new as 1985. And it won’t be long before all lead service lines in America will need to be inventoried and replaced.

Some of the biggest offenders are lead service lines (LSLs) — pipes that run from municipal water mains in the street to a home’s internal plumbing. Service lines often attach to lead-based “goose necks” or “pigtails” — shorter pipes that serve as connectors to the water main line. Within the home itself, there are other points of concern: galvanized pipes that lead particles can attach to, causing elevated and unsafe levels in drinking water over time; copper pipes with lead solder installed prior to 1986; and faucets — simple fixtures within sinks, baths and showers — that may also contain lead material.

An overview of Lead and Copper Rule mandates

Revisions to the EPA Lead and Copper Rule were made on December 22, 2020. They became effective on December 16, 2021, with full compliance required by October 16, 2024. Improvements under the new rule include:

- Using science-based testing protocols to find more sources of lead in drinking water.

- Establishing a trigger level to jump-start mitigation earlier, and in more communities.

- Driving more and complete lead service line replacements.

- For the first time, requiring testing in schools and childcare facilities.

- Requiring water systems to identify and make public the locations of lead service lines.

To comply with the new rules, communities will need to inventory all water systems, whether municipally or privately owned. Inventories must identify locations where lead materials are present in drinking water systems. If lead is discovered, a plan for replacement of known lead pipes or materials must be submitted to the EPA along with the inventory report.

How can GIS help?

Accurately mapping components such as hydrants, valves, mains and service lines is an important piece to effectively inventorying a water utility system. This spatial representation of system assets helps set the foundation for a community’s GIS. It allows leaders to make data-driven decisions about when, where and why to invest in infrastructure upgrades.

Using GIS to identify locations likely to have lead

Communities should begin by conducting a materials inventory to identify appropriate monitoring sites, calculate lead service line replacement requirements and prioritize locations for replacement. The inventory also aids in meeting the public education and customer notification requirements of the revised EPA rule. Data gathered will enable the EPA to confirm that monitoring sites are undergoing adequate sampling and allow municipalities to demonstrate they are meeting rule requirements.

An important first step in the process is to review archived water utility records, local plumbing codes and ordinances to determine which year the community stopped installing lead service lines and/or lead connectors. Next, a review of local tax records will help identify all buildings constructed prior to that date, with the assumption that there are lead service lines at those properties unless proven otherwise.

Other types of records should be reviewed as well, such as plans and specifications from water main installations, rehabilitation and/or replacement projects, plumbing permits for when existing structures were renovated or service lines replaced, or existing GIS data of service line materials and size. This is an easy way to establish an initial database of pipe material, size and installation dates. It also creates information on a large scale, which helps municipal leaders prioritize where to begin with the inspection process.

Using GIS to inspect locations likely to have lead

After reviewing records to create a large-scale inventory of locations where lead is likely present, the next step involves inspecting those locations identified. A comprehensive inspection should focus on materials at three locations:

- The service line pipe on the street side

- The service line pipe on the property side

- Materials within the on-premise plumbing systems

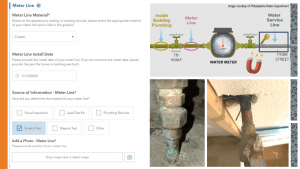

An easy place for municipalities to start obtaining information about water service line materials is by having customers complete inspection surveys themselves. This can save time and resources while also empowering citizens to be a part of a public utility improvement project that impacts them directly.

Surveys can be hosted on a variety of platforms, but one of today’s best tools of the trade is GIS. MSA has helped many communities create surveys in the cloud-based program ArcGIS Survey123, which can be easily linked to a public website and distributed via social media or mailed postcards that include a QR code to lead participants to the survey online. The surveys ask simple questions and provide guidance to help the customer determine their service line material. Customers can also take a picture of pipes coming into their home’s meter for extra documentation. The survey validates the customer’s address and creates a location in the community’s GIS system. All resulting information collected is tied directly to that geo-specific location for streamlined future reference or ultimate replacement.

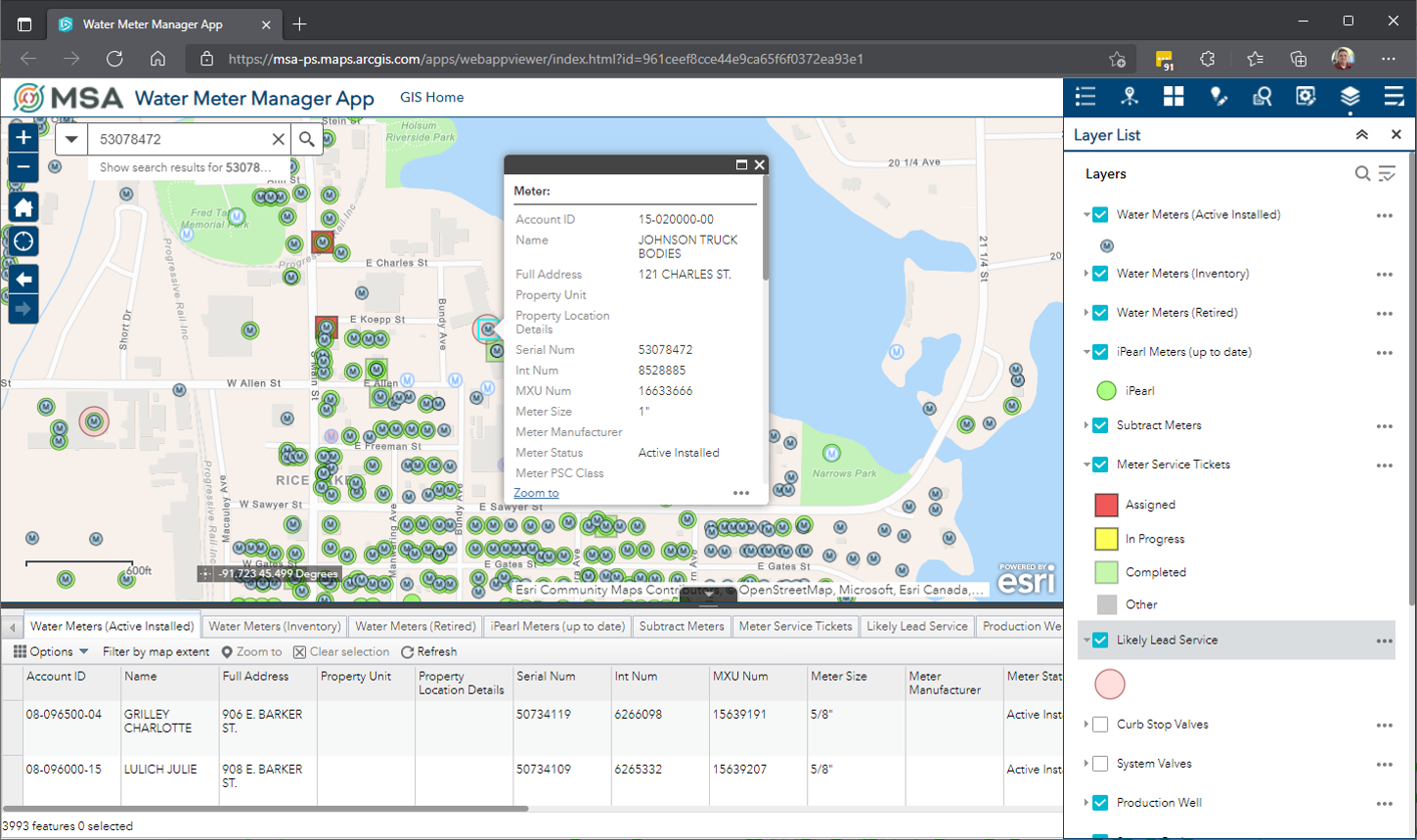

Meter data is another easy way to quickly populate service material information. Meter management databases offer a large amount of data and can easily be located into GIS through geocoding. Overlaying mapped meter locations with locations identified from records review creates a work list of specific properties to inspect. Spatial and data analysis can then prioritize the order in which properties are inspected. Lead material inspections might be the main reason to visit a residence, or the inspection can take place alongside other routine tasks, like replacing a meter or conducting a cross-connection inspection. GIS has the tools to ensure inspections are thorough and accurate through smart-form technology that guides the inspector every step of the way.

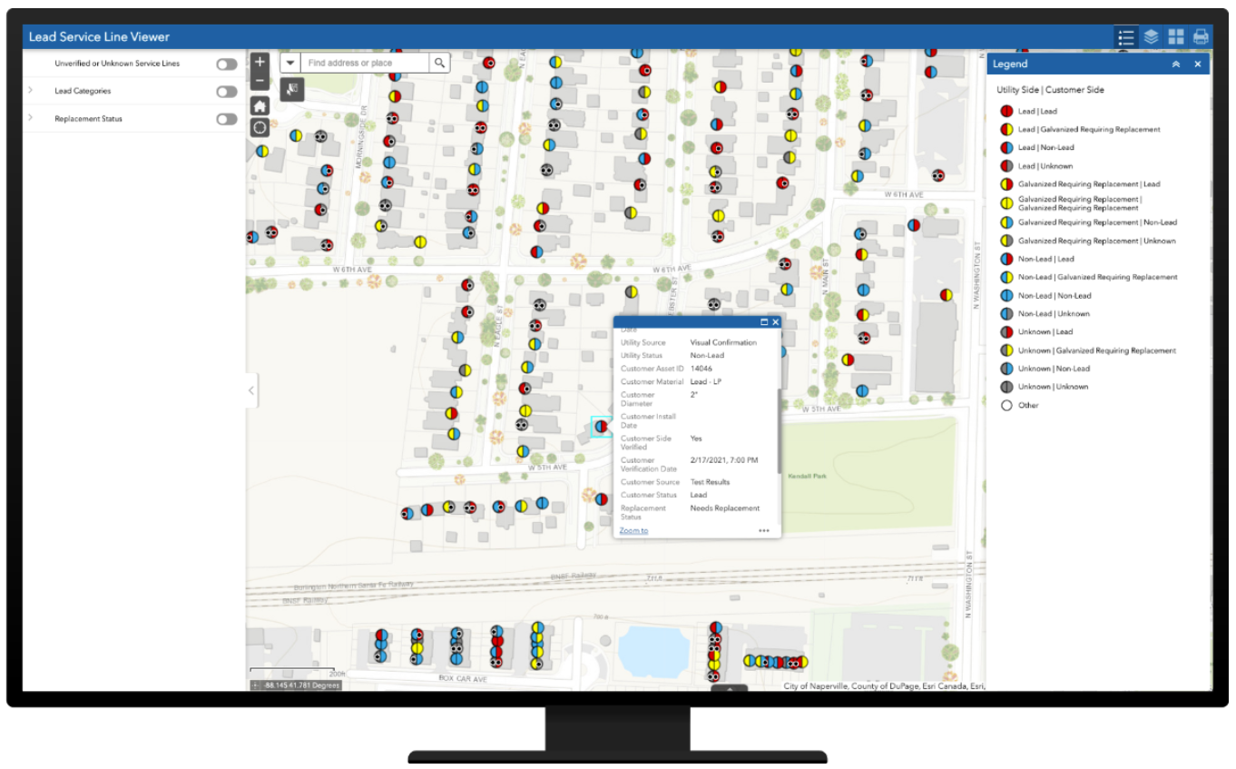

Using GIS to track progress and inform the public

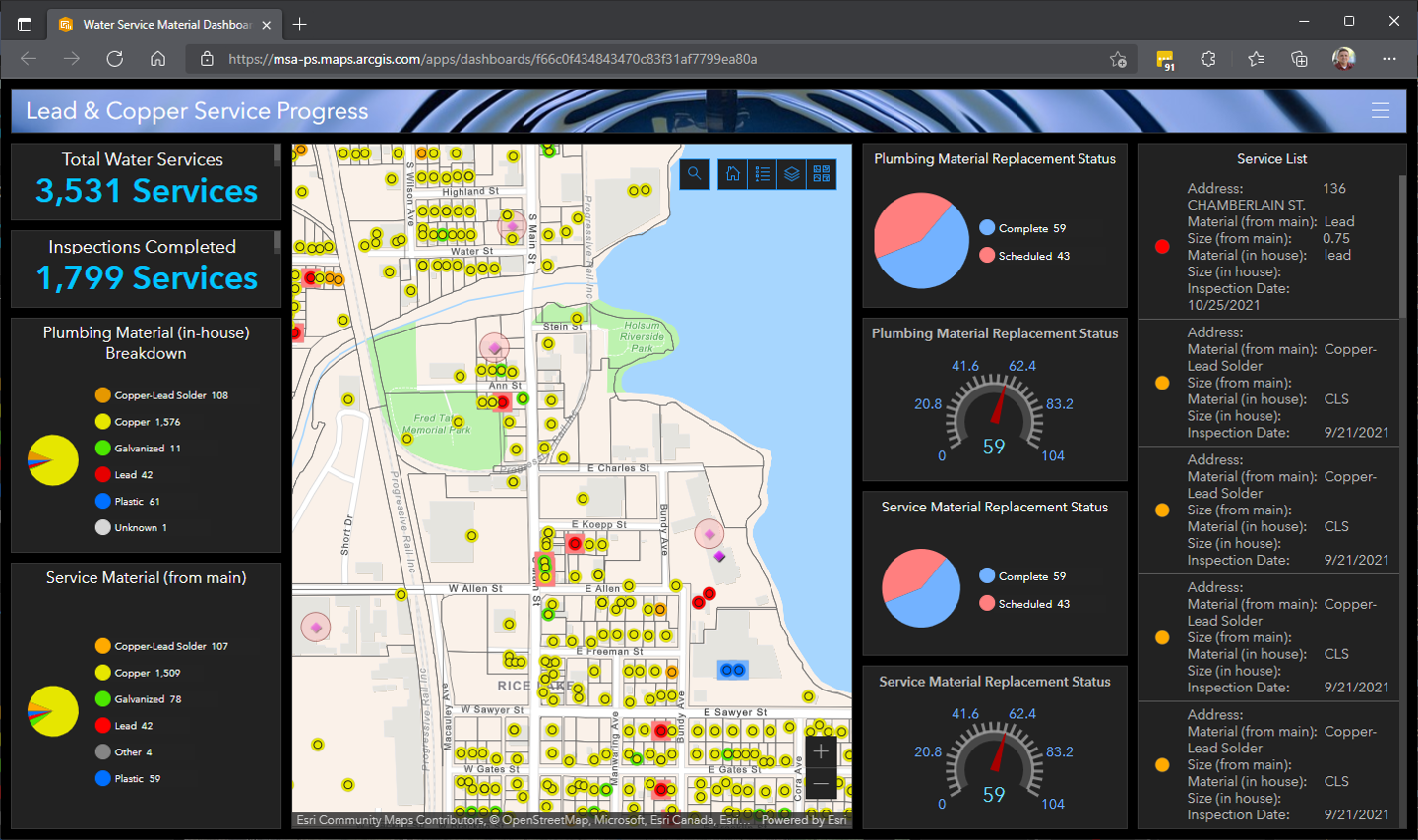

Communities are expected to make their service line materials inventory publicly accessible as part of the Lead and Copper Rule. GIS can help meet this requirement in a number of ways: East-to-use interactive mapping apps allow residents to search address locations and see what type of material the service lines are made of. Dashboard apps use data visualizations to provide residents a more detailed analysis of service line materials across the entire community. And Hub sites are GIS components that offer a one-stop location for residents to learn everything they need to know about lead and copper. From why identifying lead service lines is important, to who to contact if you’re replacing your service line, Hub sites can be configured as a community’s main location for public information.

The GIS difference

GIS can streamline the inventory and inspection of lead materials within a community. It can optimize the entire asset management process and make the identification, testing and replacement of lead service lines or lead plumbing components easy to document, manage and prove. GIS can also help determine location-specific condition, failure rate, environmental input, reliability and risk associated with the components of public infrastructure, allowing leaders to make repair-or-replace decisions based on real-time data.

Revisions to the Lead and Copper Rule require communities to not only identify locations of lead service lines but inform the public of those locations. Interactive GIS apps keep the public informed of where lead materials have been located. Dashboards update residents on replacement progress, and Hub sites provide important public information about current and future strategies.

Funding to support lead service line replacement

The Bipartisan Infrastructure Investment and Jobs Act signed into law on November 15, 2021, includes $15 billion for replacing the estimated 6 to 10 million lead service lines still in existence nationwide. These funds provide a once-in-a-lifetime opportunity to rebuild municipal water infrastructure and fortify our country’s drinking water systems.

It is anticipated that 49% of the funds will be allocated to communities as grants or principal forgiveness loans though the Drinking Water State Revolving Funds program, and 51% of the funds will be available via low-interest loans. State matching funds are not required.

While further details about the Infrastructure Investment and Jobs Act are still forthcoming, communities should initiate the process of lead materials inventory and inspection sooner than later. Preparing now will help secure the necessary funds for replacing lead materials and position municipalities to meet compliance with the EPA Lead and Copper Rule by the deadline of October 16, 2024.

GIS provides all the necessary system checks for Lead and Copper Rule compliance: it serves as a system of record for a lead inventory; it serves as a system of insight for effective lead replacement; and it serves as a system of engagement to keep a community’s staff and residents informed.

Is your community making progress? Find out in our September 2023 article: Pipe Dreams to Progress: a Status Check on LSL Compliance and companion Lead Service Line Compliance Resources tool — an easy-to-navigate questionnaire that walks participants in Illinois, Iowa, Wisconsin and Minnesota through a checklist of “if-then” scenarios to assist in identifying next steps and securing the right resources to reach the finish line.

Still have questions? Contact us today and let’s get to work.