In just over one year (by October 16, 2024), communities will need to prove compliance with revisions to the EPA Lead and Copper Rule.

In just over one year (by October 16, 2024), communities will need to prove compliance with revisions to the EPA Lead and Copper Rule. This includes conducting an inventory of all water systems both municipally and privately owned, making public the locations of lead service lines (LSLs), establishing a plan for replacement and submitting the report to the EPA.

The methods of inventory, lines of responsibility, reporting methods and deadlines fluctuate from community to community and state to state, which can make it difficult to determine which direction to turn. At the end of the day, however, communities who have not yet begun the process need to get started.

Let’s begin with an overview of the reasoning behind the EPA rule, then discuss the different means to conduct an inventory, how GIS can help, and finally — exploration of a new MSA-designed questionnaire, the Lead Service Line Compliance Resources tool, which walks communities in Illinois, Iowa, Wisconsin and Minnesota through a checklist of “if-then” scenarios to assist in identifying next steps and securing the right resources to reach the finish line.

LSL Inventory Benefits

Aside from the need to meet EPA compliance, conducting an inventory is important for a variety of reasons. Inventory documents can be used in applications for critical LSL replacement funding and can help prioritize replacement in underserved communities. An inventory helps notify customers of any presence of lead in community water systems and can help mitigate the risk of exposure and associated health concerns. The process can also serve as an important educational tool and can build customer trust through transparency and action.

Inventory Methods, Pipe Material Tests and Variations by State

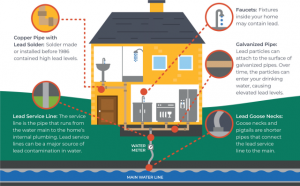

It is a misconception to think that lead is found in only very old buildings. In fact, lead-leaching components can be found in homes as new as 1985. There are two main ways to identify service line materials: an analysis of historical records and an inventory of service lines in question.

At minimum, an inventory should include a materials classification by category — lead, galvanized steel, non-lead or unknown — and should include all system- and customer-owned portions of the municipality’s distribution system. Determining the type of pipe material might include an evaluation of construction and plumbing records, water system records, distribution system inspection records or by performing one of these simple hands-on tests:

- The magnet test: A magnet will not stick to lead or copper but will stick to galvanized steel.

- The scratch test: If you scratch the pipe with a coin, you can determine the material of the pipe by the color and consistency. If the scratched area is shiny silver and flakes off, the service line pipe is made of lead. If the scratched area is copper in color like a penny, the service line pipe is copper. Scratching a galvanized steel pipe will not really affect it, so if the surface remains relatively undamaged and a dull gray, it is steel.

- The tapping test: When tapped with a hard object, a lead pipe will make a dull noise. If either copper or galvanized steel pipes are tapped, they will make a metallic ringing sound.

There are other pieces of information that may need to be collected as part of the inventory as well. These also vary from state to state. In Minnesota and Wisconsin, for example, communities need to include in their reports quite a few additional indicators including unique service line ID numbers, service line installation dates, service line sizes, the presence of any lead connectors or lead solder, and whether the inventory is being conducted in a disadvantaged neighborhood, within a sensitive population, if it was field-verified, and more.

In Iowa, inventories should include the dates of installation for both the public and private sides of the utility and note if lead components or service lines were ever present upstream. In Illinois, the inventory should also note whether galvanized material was ever downstream of lead, which would trigger the replacement of that piping also.

Image courtesy of U.S. EPA

With all the variations at hand, municipalities need to perform due diligence in researching their state’s specific requirements so that full compliance is attained.

GIS for LSL Inventory and Asset Management

Communities are being asked to collect, manage, and report on a large amount of important and nuanced data. It’s a fair amount of effort, yet this is where GIS comes into play. GIS can be used to streamline all stages of the project lifecycle — from LSL inventory to asset management and reporting.

If a community already has a GIS system in place, it can easily be configured to help map water distribution components and materials, prioritize replacement areas and track progress made. Using GIS can also assist with public education and can pull citizens in as active participants in the process. For instance, homeowners can conduct their own pipe material tests at home and upload the results to an online survey. This not only generates buy-in for the project but can also ease the burden placed on municipal staff who must otherwise conduct all the inventories themselves.

Where is the line of responsibility?

Who is responsible for the inventory and testing of water lines — the homeowner or the municipality? The U.S. EPA has drawn a line at the curb stop, marking anything inward from that (toward the home) as the homeowner’s responsibility. Anything street-ward of the curb stop should be the responsibility of the municipality. Not all communities follow this rule, however, so it is worthwhile to confirm at the local level where that line of responsibility is drawn.

Replacement Schedules, Public Notifications and State-specific Variations

After conducting a thorough inventory and testing of pipe materials, communities must then notify the public of the location of all found lead service lines and develop a plan for replacement — also due by October 16, 2024.

The degree of promptness pertaining to public notification and requirements for what to include in the replacement plan also vary from state to state. There is no one-size-fits-all answer, so communities need to stay abreast of their state’s schedules and specific terms of compliance.

Lead Service Line Compliance Resources Tool

MSA’s customized Lead Service Line Compliance Resources tool is an easy-to-navigate questionnaire that walks participants in Illinois, Iowa, Wisconsin and Minnesota through a checklist of “if-then” scenarios to assist in identifying next steps and securing the right resources to reach the finish line.

Funding Resources

There are several federal funding sources available to assist with the replacement of lead service lines in communities.

U.S. EPA

- Water Infrastructure Finance and Innovation Act

- Small and Disadvantaged Communities Program Grants

- Reducing Lead in Drinking Water Grant

USDA

- Water & Environmental Programs

HUD

- Public Housing Fund

- Housing Trust Fund

- Healthy Homes Production Grant

At the state level, we’re seeing a wide variety of options ranging from Drinking Water State Revolving Fund loans to state EPA grants and loans and Department of Commerce and Economic Opportunity Public Infrastructure grants for communities that meet certain Low- and Moderate Income (LMI) criteria. Some of these programs include principal forgiveness for disadvantaged communities; others prioritize nonprofit organizations such as schools and daycare centers. In some cases, the private property owner/homeowner is responsible for financing their portion of any lead service line replacement, but there are grants and loans available for that, too.

![]()

![]()

MSA public works and water engineers, funding experts and GIS specialists are keeping a close eye on Lead and Copper Rule developments as they roll out. We’re here to support communities of all sizes in the inventory, replacement and pursuit of funding for these municipal systems, so whatever your question or concern, please don’t hesitate to reach out.