We live in an age where technology is everywhere. It continues to change our lives and the way we do our work.

When computers entered the engineering industry, it simply became easier to accomplish tasks that had formerly been completed using pencil and paper. Designers were able to make changes faster—with a simple click of a button. While computers offered a convenient digital solution, however, the overall workflow was not altered all that drastically. Designs still required detail, and the time to ensure a successful segue to the tangible finished product.

Yet now, in a new age of technology, we see the demand for more in a shorter amount of time. Our global dependence on immediate data and at-our-fingertips results has transcended into the Architectural, Engineering and Construction (AEC) industry and affects the way we complete our projects. When creating renderings or developing concepts for a client’s consideration, two or three options are no longer sufficient. We need the capacity to explore more alternatives, to optimize the most favorable ones and remain nimble in response to changing project needs. This immediacy is a clear positive within the profession, but it also ups the ante on the types of deliverables our clients are coming to expect.

But, how — in the world of design — do we fulfill the demand for more options, the call for higher sophistication and the request for a condensed delivery timeline when our product is not a physical object? Other industries such as manufacturing have migrated towards streamlining processes and optimizing output with the aid of robots and precision machinery. We can now begin to translate a similar process into the AEC industry with such tools as generative design and automated-aided design.

Generative Design

Generative design is an innovative concept that was pioneered in the manufacturing sector and is now being applied to the AEC industry. A single definition of generative design may not exist, but Anthony Hauck, president of Hypar — a company specializing in generative design tools for the AEC industry —summarized it nicely with:

“Generative design is the automated algorithmic combination of goals and constraints to reveal solutions.”

Let’s break that down. The constraints are defined by the designer at the start of the process. Constraints might include design speed, grade requirements, or minimum and maximum depths for a pipe. Then, a computer iterates through a variety of possible solutions, learning from each step and optimizing results to meet the predetermined parameters. This mimics the traditional process that designers typically use on projects, but it allows for significantly more options to be explored.

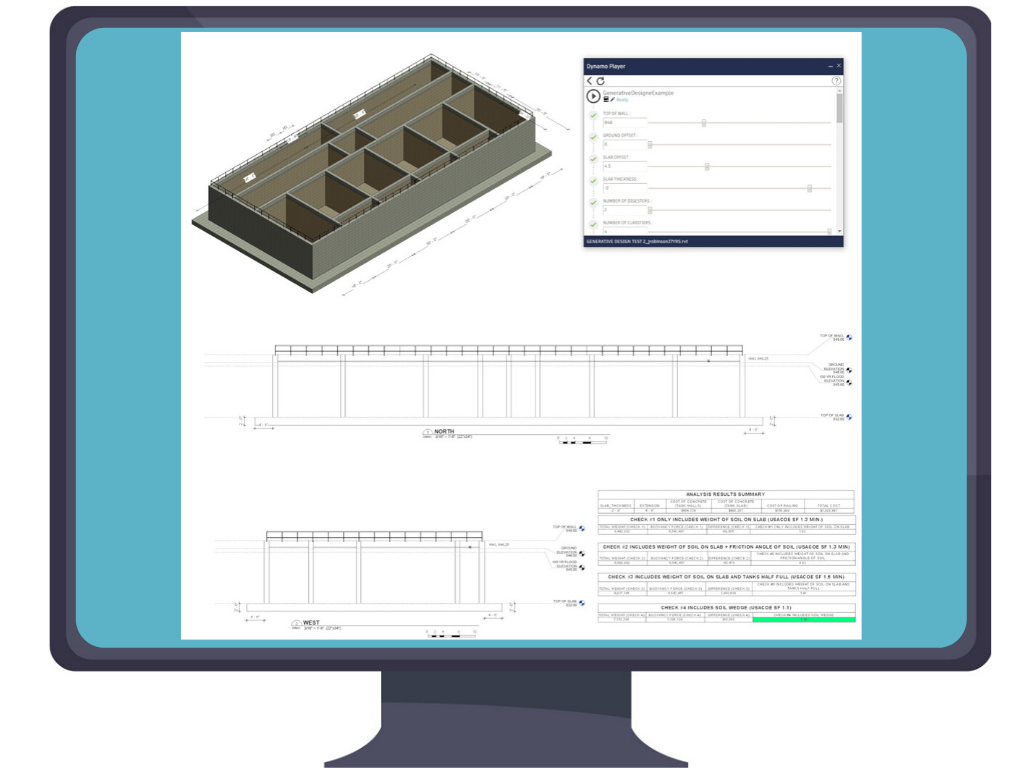

Example dashboard created in Revit to help designers and clients quickly see the impact changing different parameters have on the overall design. Simple controls allow users to interact with the model inputs with no programming knowledge required.

Generative design is not a substitute for a professional’s hand, but rather a tool that augments the knowledge and judgment of the designer. From a sustainability aspect, generative design also allows the designer to evaluate more efficient structures or ones that utilize less material. For clients, generative design aids project stakeholders in making more informed decisions about which solution they should proceed with. It also helps explain and promote the project to members of their community.

Automated-aided Design

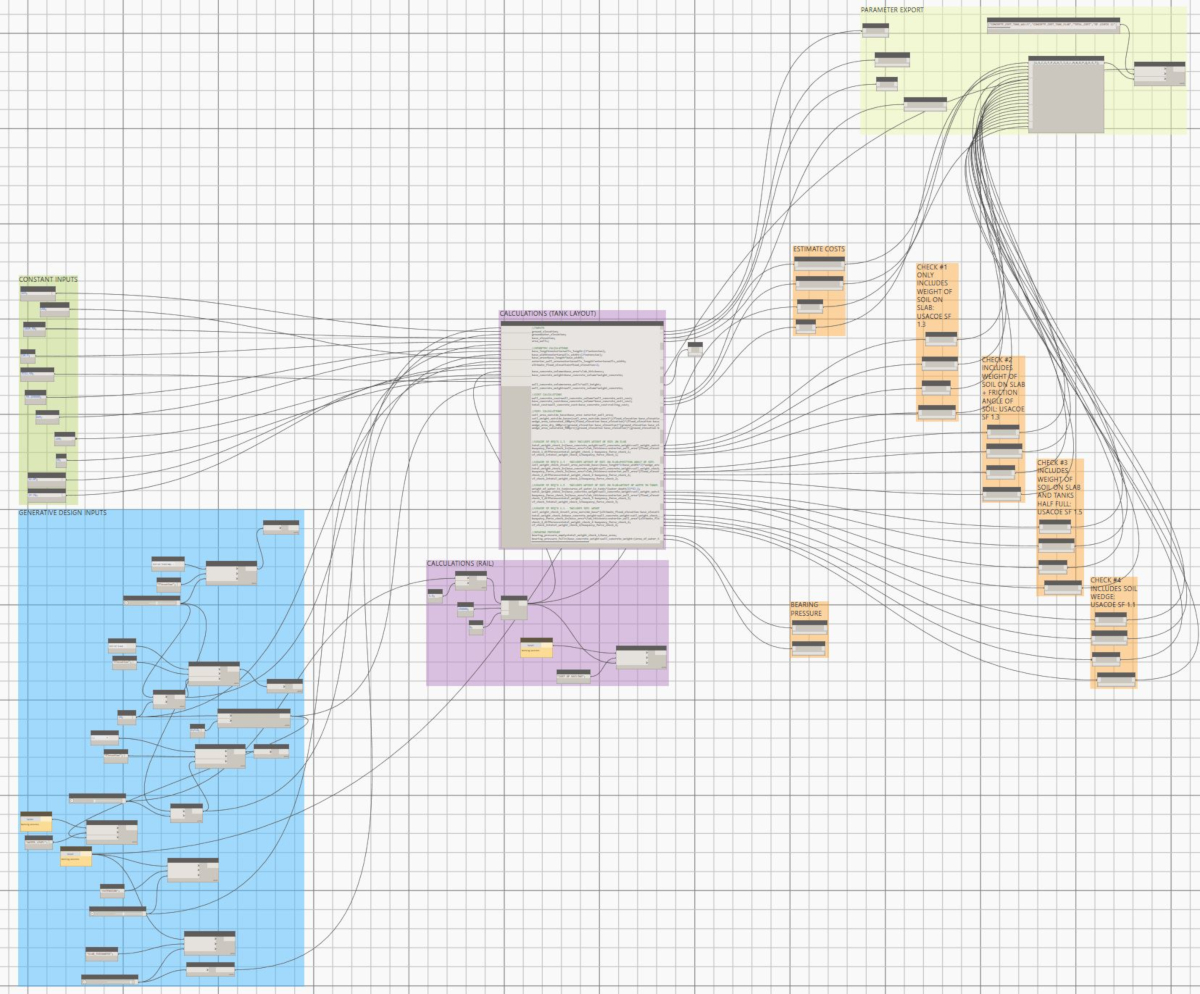

Example of Visual Programming using Dynamo in Revit

When it comes to automated-aided design, production tools such as Autodesk Revit and Civil 3D are now offering solutions that allow non-programmers ways to automate repetitive processes by using visual programming. The value associated with automation comes not only in the form of time-saving, but also in the dynamic nature of design; it allows design data to be directly mapped to outputs—inherently reducing errors.

Let’s say, for example, a designer is working on utility placement within a new building. They could develop a script within a visual programming tool for placing pipe penetrations through walls and floors. The script recognizes the conflict point between all of the walls, floors and pipes within the structure. Then, it automatically pulls different parameters such as the pipe material, wall/floor material, wall/floor thickness, pipe size, rotation, etc., to place the correct penetration. If the placement of the walls or floors were to change during the design process, the script automatically updates the location and information associated with the pipe penetrations, resulting in a highly efficient and fluid project evolution.

Smart solutions

So, is doing more in less time a good thing? Utilizing generative design and automated-aided design, designers in the AEC industry can more promptly and wholly meet their clients’ visions. They can spend more energy focusing on structure that is energy- and cost-efficient, resilient and aesthetically pleasing. They can give due attention to improving municipal infrastructure, addressing aging utilities or optimizing systems performance. Instead of spending countless hours developing spreadsheets to compare a few alternatives and mapping design data to tables for output, they can focus knowledge and experience on the goal of delivering the best possible, value-added solutions for the challenges clients face. The age of smarter working is upon us. We embrace it.