Determining the best foundation and method of construction for a bridge project requires multifaceted consideration. The process requires an intensive evaluation of location, site geotechnical and hydraulic analyses, as well as determination of the scour potential and maximum scour depth–how much sediment could potentially erode from bridge abutments or piers, as caused by moving water. There are also site constraints to consider based on the magnitude and direction of bridge loads, performance requirements, frost potential and other surrounding obstacles such as restricted right of ways, overhead and lateral clearance, and vibration sensitivities.

In the City of Park Falls, Wisconsin, all of these more standardized factors needed to be considered for the design of their much-needed replacement bridge—and then some.

Spanning the Flambeau River, with tight paper mill constraints

The new three-span, pre-stressed concrete girder bridge for State Highway 182 crossing the Flambeau River posed a number of unique foundational and environmental challenges: a shallow bedrock river with deep-water conditions, the extremely vibration-sensitive machinery of an adjacent local paper mill, a cherished recreational waterway and the subsequent need to proceed in a careful and calculated manner.

A solid foundation

Sensitive drilling shaft operation

Multi-column piers with drilled shaft foundations were selected as the best choice for the Park Falls STH 182 Bridge project, a category of foundations that transfers structural loads to a deeper stratum when a more competent soil or rock base is absent at the proposed foundation site. Due to the shallow bedrock in the Flambeau River and relatively deep water conditions, more traditional piling and sheet pile cofferdam designs were not feasible because they would not adequately penetrate the substrate. A spread footing type of foundation was equally unworkable because it caters to shallow foundations, requiring the same impenetrable sheet pile cofferdams.

Drilled shaft foundations, on the other hand, matched the site conditions perfectly. These are installed by drilling cylindrical boreholes to the requisite diameter and depth, placing reinforced steel into the column and then filling with cast-in-place concrete. Because drilled shafts do not require a hammer for installation—nor do they displace the adjacent soils—they have a minimal vibrational impact on adjacent structures, a detail critical to the success of the project.

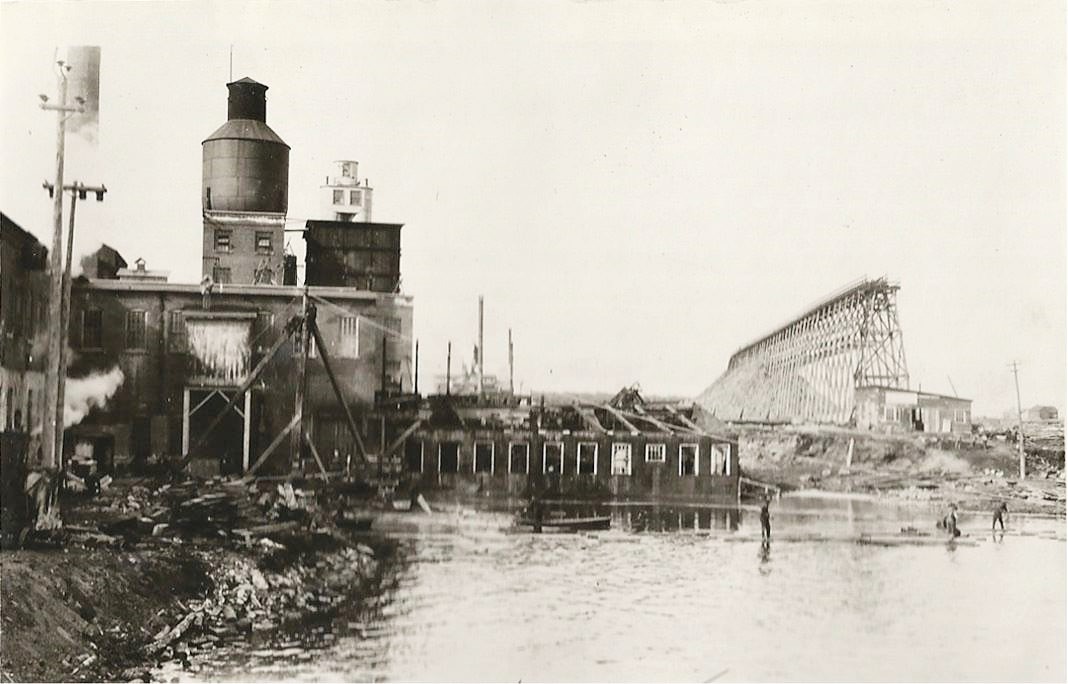

Old Flambeau River Paper mill, courtesy of company Facebook page

Good vibrations

Park Falls is a community with a long history of industrial and riverfront milling operations. Flambeau River Papers inhabits property directly adjacent—within a few feet—to the bridge project. Mill management had great concern about the impact of the drilling component of the project because some machinery key to the paper manufacturing process, located immediately inside the mill building, was extremely sensitive to vibration. There was also concern about excess movement shaking loose dust or other foreign particles within the mill buildings, which could contaminate the integrity of the paper products themselves.

Vibration-sensitive equipment, courtesy of flambeauriverpapers.com

It was imperative that MSA’s drilling and construction methods protect mill operations.

Using drilled shafts provided the advantage of lower levels of vibrations created when drilling the holes, as compared to traditional piling or sheet piling in this type of substrate. As an additional safeguard, MSA employed special vibration monitoring equipment and a vibration specialist to take readings during the design stage to determine the baseline vibrations, then required the contractor to monitor vibrations during construction to gauge bands of frequency and alert crews if they exceeded the normal or preferred range of activity. These extra safeguards provided assurance to the adjacent paper mill management and resulted in no vibrational effects while allowing the new bridge to rest on a solid foundation.

Connecting communities

Whether replacing, rehabilitating or designing around the more particular intricacies of a bridge project, one thing is certain: bridges are community connectors. They keep communities moving and guarantee safe passage while doing so. Learn more about MSA’s bridge, road and highway capabilities and know that our team will do whatever it takes to make your community projects work for everyone, with solid foundations and good vibrations at every step.