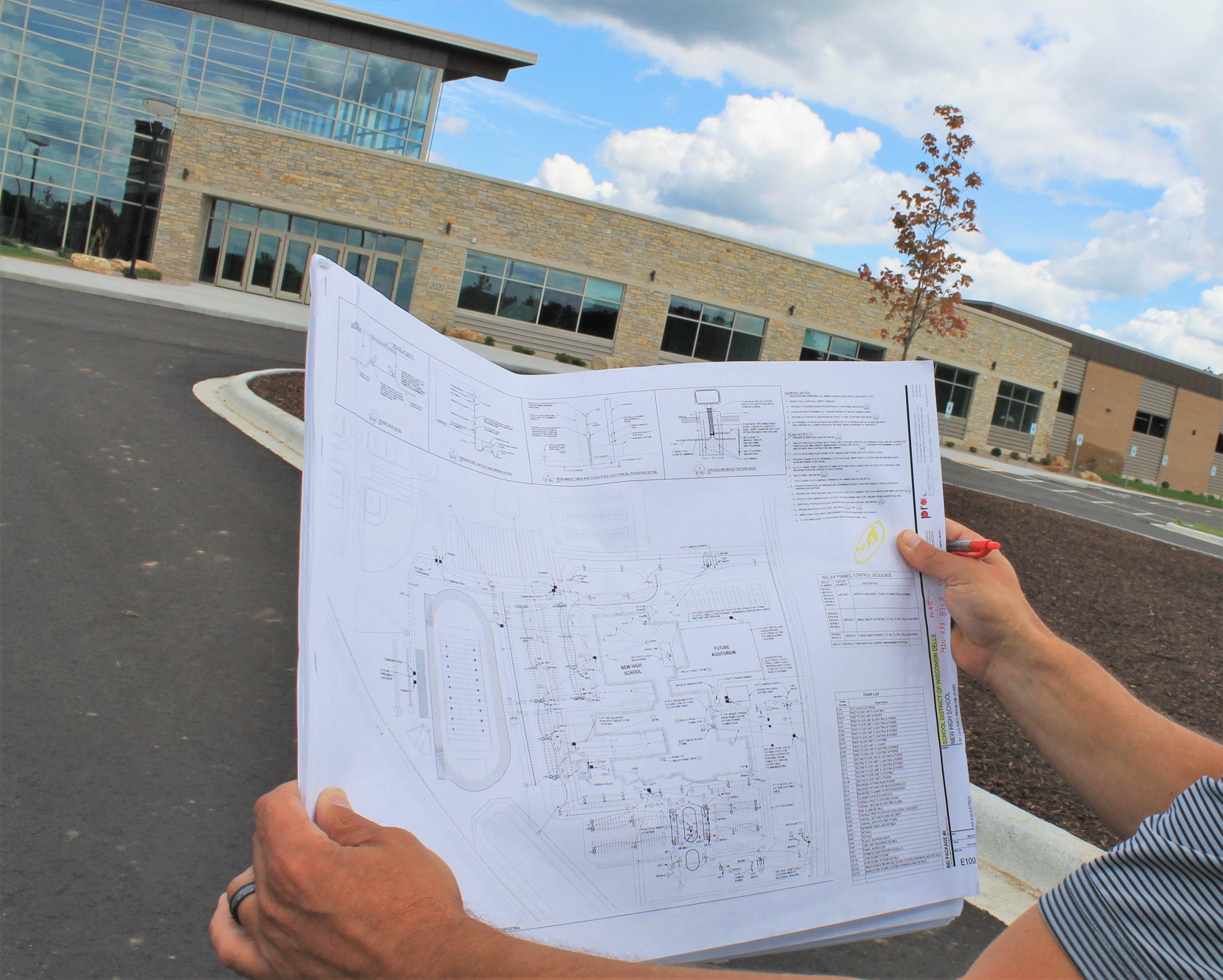

When most people think of engineering, they picture a relatively tangible end product. But, what of those who engineer the very air we breathe?

At a molecular level, we can examine and augment oxygen and carbon dioxide levels to establish a healthy balance. We can test the air quality of our indoor and outdoor spaces and standardize what is appropriate and safe to breathe. But, what happens when something like a new virus threatens our ability to protect our air? We turn to engineering and those who design, reinvent and implement heating, ventilation and air conditioning (HVAC) systems.

HVAC’s three major functions are intricately related, vital to both domestic and commercial environmental comfort and air quality. Based on the principles of thermodynamics, fluid mechanics and heat transfer, without a solid HVAC system, places such as hotels, senior living facilities, industrial complexes, hospitals, schools and airplanes simply would not be places we would care to frequent.

The current challenge in HVAC system design is the introduction of the Coronavirus, a highly air-borne pathogen with a molecular size smaller than even some of the best filtration systems can capture. This has left public and private facilities scrambling to assess their system capabilities in order to provide the safest quality of air exchange possible. Fortunately, systems can be retrofitted to significantly upgrade functionality. And, new construction projects can introduce some of the most revolutionary processes on the market. Let’s take a closer look.

Filtration

A good first step in upgrading your facility’s HVAC system is to ascertain the efficiency of your filters. This is particularly important for larger public and industrial facilities like those mentioned above. A properly high-functioning filtration system can drastically help reduce airborne contaminants, including those particles that contain viruses. HVAC systems in larger buildings generally filter air before it is distributed throughout the facility. However, these systems can be complex. Filters should be professionally recommended, compatible with existing infrastructure and the proper fit to minimize air bypass.

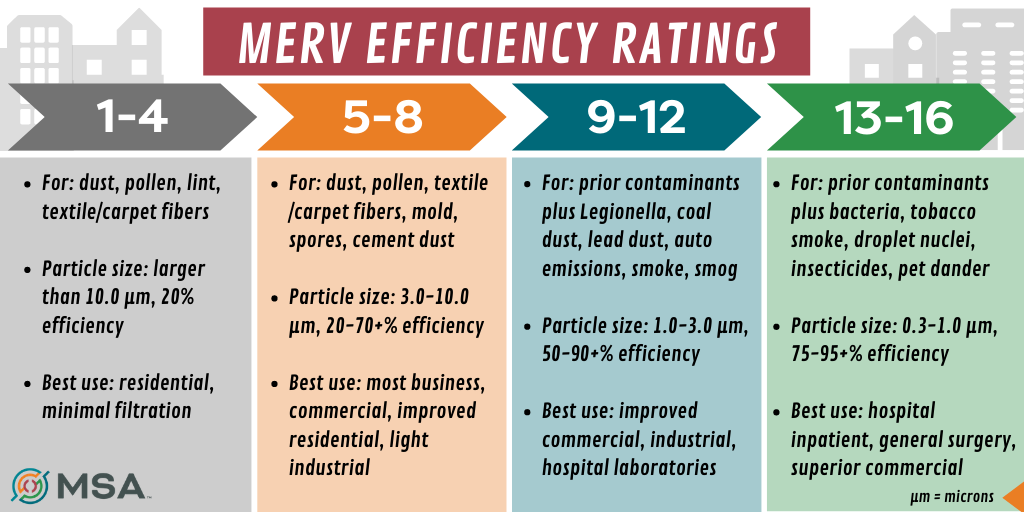

This is where Minimum Efficiency Reporting Value (MERV) comes in. MERV is the name for the system that rates the efficiency of mechanical building filters on a scale: MERV 1 through MERV 16. The higher the MERV, the better the filter is at trapping specific types of particles, as measured by their micron size. These filters are best at capturing particles that range in size from 0.3 microns in diameter up to 10. The challenge with the Coronavirus is that the particle is the smallest on record — 0.1 microns — which makes it more difficult to contain.

To mitigate risks associated with COVID-19, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends filters with a MERV rating of 13 or higher. A level 13 is at least 85 percent efficient at capturing particles in the 1-3 micron range. A MERV 14 filter, at least 90% efficient, and increasingly so as you climb the scale. The cost per filter also increases with the MERV rating, so facilities should budget to accommodate their plan for upgrades and replacements on an annual basis.

High-efficiency particulate air (HEPA) filters are more efficient yet, and by definition, are required to be at least 99.97 percent successful at capturing particles 0.3 microns in size, but are also efficient at containing particles even smaller, like those associated with COVID-19.

However, many building systems are not built to accommodate these higher-efficiency filters, and the universal installation of all high-rated MERV or HEPA filters comes with its own set of potential obstacles. Because these filters are ultra-efficient, their use can result in noticeable changes in building pressurization, akin to trying to force air through a pillow rather than through a screen door. Facility managers need to make sure the existing air handling system can overcome this change in pressure and still maintain air flow at acceptable levels. Pair this with an associated spike in energy costs and the adaptation may simply not be manageable for the long term. An HVAC engineer can review your system and help explore your best path forward.

Outside ventilation

In tandem with upgrading filters, a facility should also ensure adequate outside air delivery and the reduction of recirculated air back to the space. Following the standards set forth by ASHRAE as well as the International Code Council (ICC) — who sets minimum standards for ventilation airflow quantity — is a good start. Facilities should consider increasing outside air ventilation as much as their HVAC system can accommodate and assess the operation of building fans. If ceiling fans exist, it is recommended to reverse the flow direction to blow air upward, adjusting internal airflow patterns to be more vertical. If adequate ventilation and filtration is already in place, fans can still be used to help promote good air mixing. Technicians might also consider replacing fixed-speed fan motors with variable-speed motors in order to gain more control of airflow. Where appropriate and feasible, facility management can also open windows to allow outside air directly in or consider installing a Dedicated Outdoor Air System (DOAS) to maximize the amount of outside air possible into the space.

Having the ability to override building controls to provide more or less ventilation can also be an effective, albeit temporary, way to reduce the spread of an air-borne disease. A caveat to this approach is a potential shortfall in heating and cooling capacity. A system may have the flexibility to provide this override, for instance, but not necessarily the capacity to keep the building at a desired temperature or humidity level during this operation.

Ultraviolet technology

Ultraviolet (UV) energy is a potentially powerful tool in the fight against COVID-19, but has its own set of disclaimers and cautions. The positives are that UV energy inactivates viral, bacterial and fungal organisms, rendering them unable to replicate. As such, UV applications are germicidal in nature and can be installed inside facility HVAC systems and associated ductwork, in safe upper air spaces of rooms or on surfaces, disinfecting when in operation. Designing and sizing larger UV disinfection systems can be quite complex with careful consideration as to where and when it is utilized.

Bipolar Ionization

Emerging as a one of the safest, most effective systems for removing harmful pathogens in buildings is bipolar ionization. With this technology, engineers and HVAC systems designers can either upgrade existing systems or implement early in the design process to provide facilities with the most sophisticated technology on the market today.

This is not entirely new technology. In fact, bipolar ionization first arrived in the United States in the 1970s as a means to control pathogens in food manufacturing. Here’s how it works in HVAC systems: Bipolar ionization units can be installed in a variety of places throughout a building: in fan inlets, interior duct walls or duct floors. Units use an electronic charge to pull water vapor from the air and create a cold plasma field filled with a high concentration of positive hydrogen ions and negative oxygen ions. As these ions travel through the air, they attach themselves to any pathogens, particles or gases they come in contact with, surrounding the harmful substances and depriving them of vital life-sustaining hydrogen. They also attached to things like droplets expelled by human breath, key to the transmission of viruses such as COVID-19.

On the side, the ionization field also causes dust particles to conglomerate into larger masses, dramatically improving filter efficiency. It also breaks down Volatile Organic Compounds (VOCs) in the space, thereby reducing harmful chemical effects and helping to eliminate odors. It does so in a manner that creates ions without creating ozone or other harmful byproducts. This technology is already in use by many airports, hospitals, arenas, universities and schools and is a worthy option for facilities looking to upgrade existing systems or maximize operations within new construction projects.

A more resilient future

COVID-19 will likely not be the last pandemic the world sees. Preparing our buildings and building systems now will help us adapt to what the future brings and better withstand similar challenges. If you have questions about HVAC design or what technologies might be a good fit for your facility, we’re here to help.